AIDEVI professional nutritional supplement OEM service: helping you build a high-quality health brand

Who are we?

We focus on:

Customization of high-end functional nutritional supplements

Development of multi-dosage forms and multi-ingredient compound formulas

Flexible small batch ordering and fast delivery

Full-link quality assurance system

How can we help you?

We provide full-process OEM services from formula development to production and delivery, including:

| Service module | Specific content |

| Product formula development | Based on customer needs, we provide ingredient matching suggestions for popular functions (such as NMN, liver protection, anti-oxidation, whitening, sleep aid, etc.) and support original formula development. |

| dosage form customization | Support tablets, capsules, soft capsules, powders, granules, liquids and other dosage forms to meet different market preferences. |

| raw material selection and procurement | Strictly select globally certified raw materials, such as NMN imported from Switzerland, GABA from Japan, fish oil from the United States, sheep placenta from New Zealand, etc., with COA reports attached. |

| production and processing | Own GMP factory, equipped with 100,000-level clean workshops and automated equipment, can produce millions of capsules per day. |

| packaging and label design | Provide bottle type/label/color box/instruction manual design to meet FDA and EU regulatory requirements. |

| compliance export document support | Provide MSDS, COA, SGS, FDA registration documents, etc., to support global customs clearance and export. |

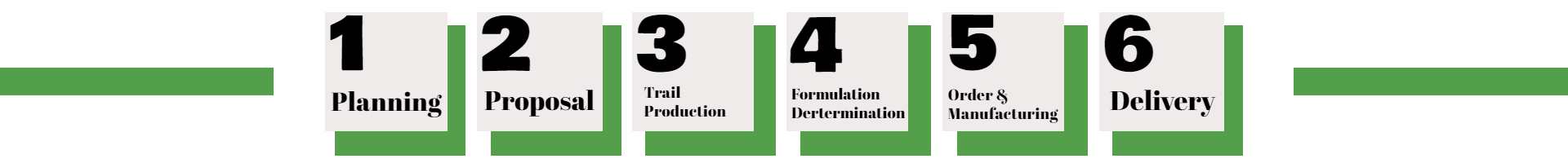

Step 1: Planning

Selecting ingredients that fit the product concept you have.

Anti-Aging & Antioxidant: Collagen, Nicotinamide Mononucleotide (NMN), Coenzyme Q10, Resveratrol, Astaxanthin, Vitamin E, etc.

Whitening Effect: Glutathione, Vitamin C, SOD, Nicotinamide, etc.

Liver Health: Curcumin, Choline, Silymarin, Spirulina, Inositol, etc.

Sleep: Gamma-Aminobutyric Acid, Tea theanine, Ghana seeds, Chamomile, etc.

Selecting methods that fit the product concept you have.

Blending Technique: Crafting the Capsule Mixture

Wet Method: Creating Capsules through Wet Granulation Mixing

Dry Method: Capsule Production using Dry Granulation

To produce these capsules, the first step involves gathering the necessary materials. Once all materials are prepared, they're mixed with hot deionized water through vacuum blending in a machine. Over time, additional hot water, dyes, and opacifiers may be incorporated into the mixture if needed. Once prepared, the blend is molded around steel pin molds to create capsules of the correct size and shape. The two ends of the capsules are then dried simultaneously. It's crucial to monitor temperature and humidity levels to ensure the capsules dry optimally.

Step 2: Proposal

Proposing products that fit the product concept you have.

The rigid gelatin of our capsules acts as an effective barrier against oxygen, preserving both the capsules and their contents. Gelatin shells additionally contribute to prolonging the capsules' shelf life. Smaller capsules are not only easier to swallow but also help mask any bitter tastes from the ingredients.

Gelatin Capsules: Derived from animal by-products, such as beef or cattle.

Vegetarian Capsules: Composed of hydroxypropyl methylcellulose, a chemical compound, water, and cellulose.

We offer a diverse range of approximately 2500 capsule formulas that align with current trends. Gelatin, a component in gelatin capsules, contains collagen, providing both protein and two essential amino acids: glycine and proline.

Step 3: Trail Production

Prototypes are created in the laboratory according to the product concept. Prototypes will be up for about 14 days for new requests and about 7 days for re-makes.

Step 4: Formulation Determination

After calculating the cost of bulk production, a suitable container and a box for the product is determined.

Several laboratory tests will be executed in order to confirm container compatibility with the product as well as the product stability. These tests include volume capacity, pump discharging and thermal stability.

Step 5: Order & Manufacturing

A quotation will be issued based on quantity, volume, trade terms etc. After agreement upon quotation, we will kindly request a PO from you. Once the product specifications are determined and a PO is issued, we carry out the production based on the requested delivery date.

Step 6: Delivery

We deliver products to specified location on scheduled delivery date.

After a series of thorough inspections (bacteria inspection, visual inspection, leakage inspection, etc.), products that are qualified will be delivered to the agreed location on the agreed date.

Why do customers choose us?

5 reasons why customers choose AIDEVI:

100% GMP factory self-production, quality control

Support original/specified formula, flexible proofing

Small batch order, support brand testing and e-commerce first launch

Optional "finished product spot + OEM" mode, fast listing

One-on-one follow-up by exclusive project manager, timely after-sales

Contact us now

Phone Number: +1 (310) 654-1079

Email us at: kevin@aidevi.com